Description

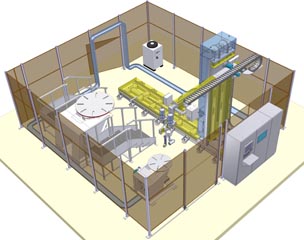

The robotized automatic equipment Robo 259 has been designed for P.T.A powder welding of pieces having big dimensions for different sectors of the industry and especially Oil&Gas . In above configuration the equipment is dedicated to the cladding of discs with diameter until 900 mm, cones and cylinders lenght 800 mm and weight until 500 kg., tricentric profiles and linear profiles : the welding is done in flat position so is necessary the combination of rotating movements, oscillation, torch positioning and rotary table tilting. The structure has a stroke of X axis 3500 mm, Y 1500 mm and Z 1400 mm (but dimensions can change and equipment can be customized according to the needs of the customer).

Features

The automatic equipment Robo 259 installs a PTA 300i welding machine complete with:

• welding torch YZR500 for externals, working range from 40A to 250A continuous, flow 0,5÷3,0 kg./hr.

• welding torch YZR500 for internals (diameter min. 130 mm), lenght 600 mm, flow 0,5÷3,0 kg./hr.

both torches have a fast connection for the immediate change while the sobstitution of the electrode is done without the nozzle disassembling.

• Mitsubishi M700 Numeric control for the control of axes movement and welding.

• Remote console for the control of axes movement and welding.

• Nr. 2 powder feeders AP High Capacity, loadkg.20 each, flow from 0.5 to5 kg/h with heater and tilting device.

• Rotating table 1: capacity kg.500, diameter 500 mm, tilting0-90°.

• Rotating table 2: capacitykg.3000, diameter 1800 mm, tilting 0-90°.

• Stick-out torch/piece automatic with Arc Voltage.

• Welding pool check and monitoring of the equipment controllato from external with video system.

• Safety barriers minimum height 2 mt. with sliding doors to help the charge of the pieces.

• Remote assistance device.